Fast, inline testing with no compromises. Monitor wafer lifetime, sheet resistance, and trapping with the comprehensive accuracy of an offline tool and an optimized industrial software package.

Product Overview

The calibrated measurements that have been developed for the Sinton Instruments WCT-120 offline lifetime tester can be applied inline to accomplish sophisticated process monitoring for an industrial production line.

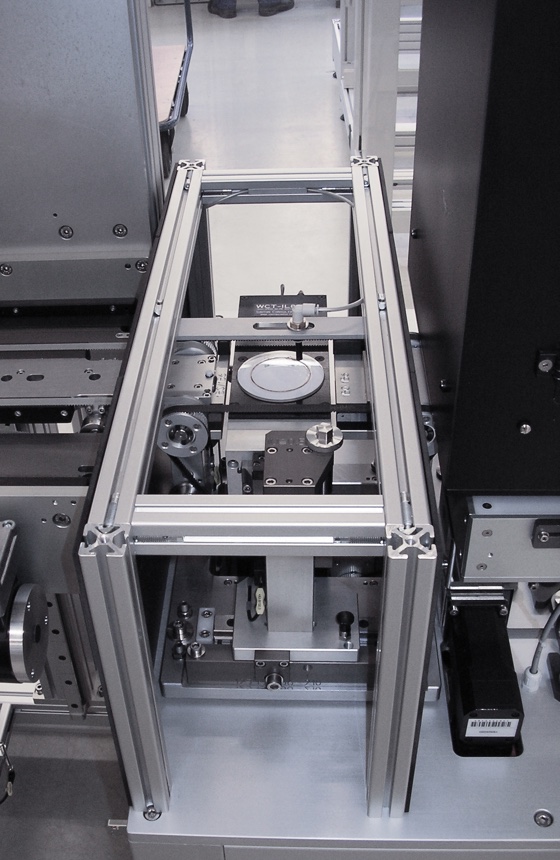

The IL-800 offers a single, large-area measurement of wafer lifetime which balances the effects of grain boundaries or growth variations. The measurement unit with its integrated excitation source may be mounted under or over a wafer track to characterize each passing wafer with our calibrated non-contact sensor.

IL-800 System Capabilities

Primary application:

Step-by-step monitoring and optimization of the production line, using measurements on product wafers at key stages in the process.

- Monitoring incoming wafer quality (lifetime, sheet resistance, and trapping)

- Monitoring phosphorus diffusion quality

- Early detection of wafer contamination from water, chemicals, furnaces, or wafer handling during the process

- Maintaining optimal surface passivation quality from the nitride deposition

Further Information

For key features, specifications, and additional information, download the IL-800 product note (PDF – 603k).

Integration Overview

We welcome inquiries from automation vendors who require a reliable and cost-effective inline lifetime measurement, with professional support and training. We also work directly with R&D and other small fabs and their choice of automation supplier to integrate the IL-800 into any metrology workstation.

The standard operating software has allowances for rapid prototyping and testing upon delivery. In the automated mode, the software client offers vital wafer results to a server database, using options such as a TCP or Profibus interface. Sinton Instruments’ characteristic reports of minority-carrier dependent lifetime are also standard.